Cold Chain Technologies (CCT) hasn’t shied away from tough discussions in recent years, in order to overcome well-documented supply chain challenges. A commitment to close partner and supplier relationships hasn’t just helped to navigate challenges in recent years, but is also paving the way for positive contributions to the world’s sustainability efforts in the future. Nicholas Tassone and Paul Della Villa did their own ‘straight talking’ here, to emphasise the importance of collaboration and digitisation in CCT’s ongoing evolution.

Hi Nicholas. With more than 50 years of experience, CCT has a strong market reputation. How would you describe its evolution, and current status?

Cold Chain Technologies (CCT) is now a leading global provider of reusable, sustainable, thermal packaging, and digital solutions for the shipment of temperature-sensitive material; principally serving the life sciences industry.

As you say, we have more than 50 years of proven product assurance in transit, leading to our reputation now as the life sciences industry’s most innovative and dependable provider.

When you partner with CCT, you benefit from resilient, high-performing systems, cost-effective & proven designs, sustainable options, compliant and connected solutions, unrivalled engineering expertise, and industry-leading customer service.

In terms of our current status, as the global leader in reusable and single-use sustainable thermal packaging shippers for the life sciences industry, we are committed to the safe transport of life-saving medications and also to environmental leadership.

As part of our three-year Strategic Plan, we have embarked on a major sustainability journey to: positively impact the health of our communities and our planet through the safe and sustainable transport of medications; to generate social and environmental change to benefit the planet, our partners, and global health; and to reduce 60 million pounds (lbs.) of landfill waste by 2025.

Finally, we are looking to decarbonize our products and services based on a circular economy model.

Click Below: view the content in magazine format

And, briefly, what is your role in this ongoing effort?

My role as Vice President of Global Strategic Sourcing and Operational effectiveness, enables CCT to optimise our supply chain partners and their manufacturing locations. We have the ability to deliver across the globe due to partners and locations that are – and continue to be – established.

We are working internally to better understand the manufacturing footprint, make calculated decisions as around the manufacture of key product lines that will greatly reduce lead and transit times to our customers.

My team is also responsible for the expansion of our global operations network. This will allow us to open new CCT-operated and partner-operated physical sites (manufacturing and distribution networks) across the globe.

You always have an eye on what’s coming from an industry trend standpoint. Where do you perceive the current challenges to be, to that end?

Our current challenges revolve around determining what our stocking inventory levels should be. As we are coming out of supply chain constraints of the past few years, many customers have stocked heavily on finished goods, and we have done the same with long lead time materials. We are therefore working closely with customers and suppliers to right-size inventory levels.

This includes straight-talk conversations to determine what current capabilities are, as well as discussing any constraints. For far too long supplier discussions have been: “yes we can handle the volumes, we can handle the requested lead-times.” When, in reality, equipment and materials weren’t available, and there really wasn’t time to discuss alternative solutions.

As companies are right-sizing inventories, demand continues to climb. Suppliers that have not moved materials have taken down stocking positions so when new demand converts into new orders, the chain is placed under huge stress once again.

What is your strategy to combat this particular issue?

Supply chain lead times have challenged all organisations and we weren’t exempt from that. We have faced challenges of lead times extending in some cases from two weeks to 20 weeks, but have focused on the importance of partner relationships on a global, holistic scale.

We worked with many locations and had to make sure we were tooled up where the labour and manufacturing capacity was at all times, to ensure we could deliver a steady state of materials during some incredibly trying times for all. We worked with manufactures to establish stocking positions and created several versions of programmes depending on the commodity, as well as the increasing lead time situation.

“Straight Talk” is also very key to our suppliers and our customers. We all need to understand current, true, lead times. We can no longer accept estimated delivery dates that may be too aggressive and may (probably will) slip. The supply chains are running too tight, and suppliers and manufactures are running very lean due to either labour issues or raw material constraints.

Customers need to understand what their real delivery dates are going to be. They need to be able to plan accordingly and if they need to come up with a backup plan, they need to be given that opportunity ahead of time to ensure they are prepared for a worst-case scenario. Our customers rely heavily on being able to ship medications and in some cases, lifesaving medications; so the better prepared we are the better prepared they are.

Paul, I’d like to bring you in at this juncture, to explain the role of technologies and digital transformation as part of this effort to become more predictive, and to enhance communication levels across the chain.

The digitisation of supply chains is important for both Cold Chain Technologies to manage our product supply chains, but also downstream to our customers.

Upstream, CCT has focused on improving our ERP, forecasting and demand management tools to help automate and streamline supply and inventory management. One of the key success factors is working internally with our supply chain and sales teams to ensure clean data input through our S&OP process, and to make sure the correct data and signals are driving our internal supply chain. The old adage of garbage in and garbage out holds true. By focusing on the data within our systems, we are able to improve our ability to react to the ever-changing pharmaceutical packaging market.

Downstream, CCT is focused on bringing tools to market to help provide many of those same signals we use to help provide additional visibility to our customers. In the pharmaceutical supply chain, outside of the medicinal products themselves, there are three key pillars of the supply chain: Packaging, Logistics and Monitoring (Temperature). Our focus has been on building and developing tools that help to interconnect the other two legs (monitoring and logistics), which allows our customers to get a consolidated view of their entire logistics, and to identify areas of risk.

By connecting the different supply chain signals with clear defined data, we are helping to drive our customers’ supply chains to be able to leverage newer machine learning and artificial intelligence technologies which are the future of the industry.

Paul, to confirm, where have you channelled investment most prominently when it comes to this digitisation effort?

Within our own supply chain, we are leveraging our ERP, demand planning and CRM systems to provide a clear and clean vision of our demand needs. We have also invested heavily in digitised tracking tools to manage our reusable/rental packaging business. While the tools are important to our success, identifying the processes and dataflows are equally as important in driving a successful SCM strategy.

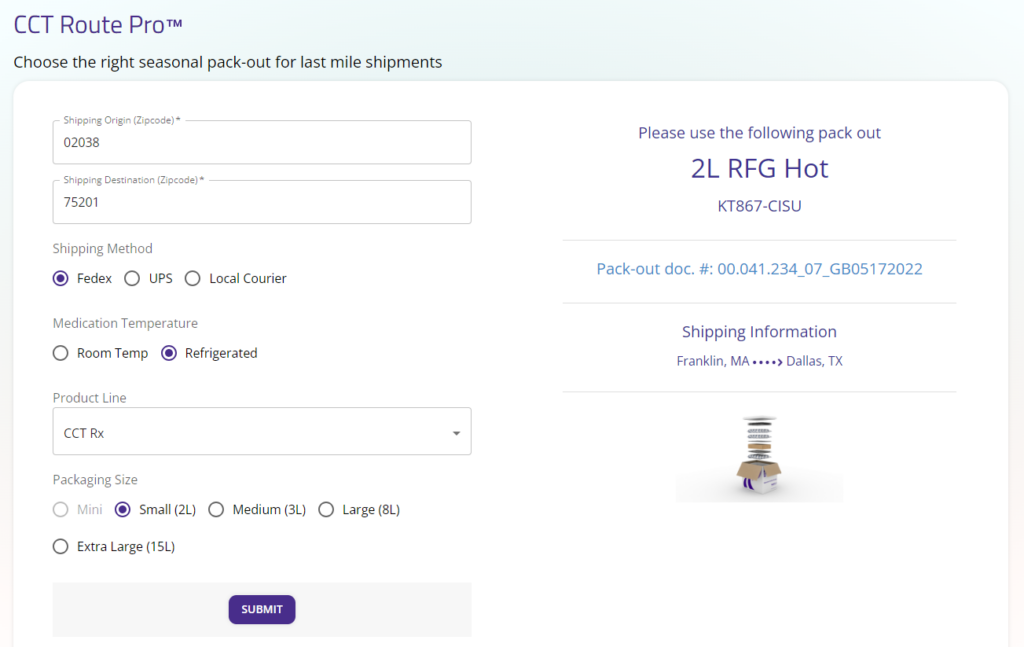

For our customer-facing applications our focus has been to digitise the ordering and tracking process (ecommerce) as a conduit to provide more information to our customers. In certain instances, our self-designed, bespoke tools allow our customers to order for same-day shipments and integrate full track and trace ability which is a goal across the supply chain.

In conjunction with our Cold Chain Technologies Smart Solutions Platform, we have focused on integrating with TMS systems, Track and Trace platforms as well as IoT technology tracking platforms; to give customers a holistic view of their temperature-sensitive supply chains.

Back to you, Nicholas: blending this ‘man and machine’ advantage when it comes to communications and more seamless operations, how vital have your partner relationships been to this strategy’s success?

I feel vendor relationships are the key to success when you are in very tight and difficult times. Being straightforward with discussions and expectations has been instrumental throughout my career and has massively helped in recent years.

As a key starting point and example of positive partnerships, you could look at the topic of sustainability. CCT and many of our suppliers are members of the Sustainable Packaging Coalition (SPC), a membership-based collaboration that leverages the power of industry to make packaging more sustainable.

As the leading voice on sustainable packaging, we are passionate about creating packaging that is good for people and the environment. The SPC’s mission is to bring sustainable packaging stakeholders together to catalyse actionable improvements to packaging systems, and to lend an authoritative voice on issues relating to packaging sustainability. Along with that, we’re working with several large, recycled material manufacturers to develop a coalition directly focused on the life sciences industry.

Content Sponsors: Astro Chemicals, Cellofoam & Crown Packaging

And more broadly, how vital has this approach to industry collaboration being in combating those aforementioned ‘tough times’?

Supply chain issues were pretty familiar even before the advent of COVID-19 and its legacy of complications. However, when the global health crisis upended business as usual, the need for truly effective supply chain management became paramount. Since 2020, the industry has spiked, revealing the difficulties caused by a lack of communication, regardless of advances in technology and processes. We now know a successful supply chain is ultimately built and maintained on supplier relationships, in the never-ending pursuit of common objectives.

What do you believe constitutes a ‘positive’ relationship then, to help navigate more challenging periods?

CCT believes in showing respect, being honest, and continuously letting our partners and their workforces know how much we appreciate them and the long hours they must put in to guarantee all-around success.

Going back to sustainability, this includes bringing partners and suppliers with us in globally significant efforts. For example, our suppliers have aligned with our focused on re-engineering single use products to aid us in our goal of reducing 60 million pounds of landfill waste by 2025. This includes decarbonising their products and services, exchanging the typical cycle of make, use, and disposal, with as much material reuse and recycling as possible.

Extending the life of products and materials prevents the overgeneration of waste. Their extensive single-use sustainable and reusable offerings help customers reduce their CO2 emissions, avoid landfills, and slim their carbon footprints.

Naturally, CCT’s supply chain strategies and methods are impacted by this strategy. CCT works with several key suppliers that are focused on recyclability and biodegradable production materials. Our company’s interim milestone of reducing 25 million pounds of landfill waste by the end 2023 was recently surpassed in October 2022; achieving 30 million pounds instead.

This alone is a fantastic achievement, and I understand it has been formally recognised too?

Indeed, CCT was awarded a 2023 silver medal sustainability rating from EcoVadis, the world’s only universal sustainability ratings provider who assess companies and their commitments to ESG.

They recognised that, through our extensive portfolio of sustainable offerings coupled with our digital platform for tracking and decision support, we are reducing the negative impact on the environment and helping the life sciences industry achieve a reduction in CO2 emissions, landfill waste, and more. At CCT, we take our commitment seriously and will continue to invest in the development and growth of sustainable solutions for the protection of our world.

Brilliant, congratulations! And this is also very commendable as a future-looking mission. Is there anything you would like to add to confirm what you hope to achieve in the industry, in the years to come?

We want to continue to design and deliver temperature-controlled distribution solutions that meet the high quality, performance, and regulatory expectations of the life sciences industry.

Moreover, we want to be the mission-critical partner that life science organisations rely on to protect their temperature-sensitive products throughout the global supply chain. We will pursue innovation and excellence in all aspects of our business to meet this goal; making a positive difference in the world as we do so.